EnviroMail 38 Update Canada

Subcontractor Safety Performance Reporting and Positive Performance Indicators

As we approach ‘World Day for Safety and Health at Work’ on 28 April, this is an appropriate time to share ALS Canada’s best-ever safety performance outcomes for 2023/24, in support of our clients.

Many companies have a key focus on safety management and protection of their staff, contractors, and communities. In the oil & gas, mining, water, and industrial sectors this can be even higher due to elevated risk profiles and strong safety cultures, built over decades.

ALS Canada Environmental 2023/24 Safety Outcomes

Our last two recordable incidents involved cuts from glassware. These have resulted in additional campaigns to continually educate staff and increase controls for sample bottle unpacking and glassware washing, plus a focus on removing any glassware with the slightest chip or crack.

| Safety Outcomes | Environmental Division Canada |

| Current LTIFR | Zero |

| Current TRIFR | Zero |

| Days since last LTI(1) | 1,362 |

| Hours worked since last LTI | 4.65 million |

| Days since last recordable incident(1) | 550 |

| Hours worked since last recordable incident(1) | 1.96 million |

| ALS Positive Performance Indicator (vs target of 90 and maximum score of 150) | 150 |

| Current five year moving average LTIFR (per million hours worked) | 0.37 |

| Five year moving average LTIFR reduction in the last 10 years | 79% |

ALS is also moving to smaller, more robust bottles which can significantly decrease the risk of breakage. Smaller bottles benefit both ALS and our customers by contributing to reduced manual handling. Careful packing of glass sample containers in coolers by ALS and our customers also reduces risk of cuts for all.

ALS, one of the largest global testing companies, is a leader in safety – taking care of our people in laboratories and on the roads, and also continually focusing on innovation to ensure customer safety. ALS globally maintains being ‘Safe’ as a company core value. This puts safety first as our most important priority in everything we do. Safety is at the forefront of all decisions to ensure the protection of staff, clients, and the stakeholder community.

Positive Performance Indicator System (PPI)

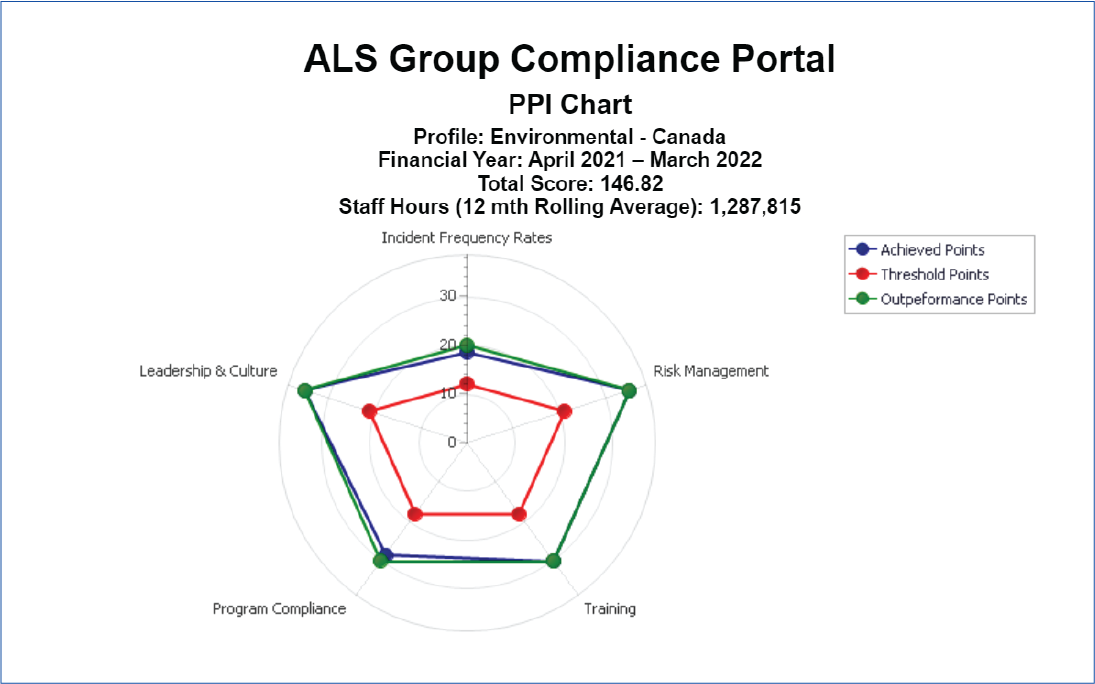

ALS implemented a PPI system globally many years ago. This tracks not only the traditional lag indicators of LTIFR and TRIFR, but also the lead indicators of a good safety culture including program development, risk management, training, and leadership. This produces a scorecard for each site/business, which resets at zero each year in April. The scorecard measures performance, and as targets are achieved and maintained, the score typically increases towards the ALS financial year-end (March 31).

The PPI Scorecard contains 13 key metrics that total 120 points but allows strong safety performance to be recognized via out-performance ratings, allowing a maximum possible collective score of 150. ALS Canada has delivered a very strong safety result again this year, with a combined total of 150.0 out of a maximum 150. This was the highest of any ALS Environmental region globally and is a credit to the local safety/management team, our staff, and our customers. Pleasingly, we were LTI free and TRIFR free for another 1.32 million hours worked and achieved perfect scores on Training, and on Leadership and Culture. The ALS Canada scorecard follows with metric categories listed adjacent.

What does this mean for ALS Customers?

Knowing that your laboratory provider is focused heavily on safety is important if that aligns with your organizational culture. What should our customers see when dealing with ALS? We would expect you to see us proactively talk about safety, share what we have learned, constantly strive to innovate on safety, and have a strong focus on helping your team be safer in the field when sampling. Each year we take further steps to reduce sample sizes, this year completing two key projects that reduced one litre and 500 mL bottles for Phenols and BNA (base/neutral acid) testing in water samples. Further projects are underway targeting removal of another 4-9 tonnes of samples being handled annually by ALS Canada clients and staff.

We hope that our customers are also seeing this continued reduction in incidents, and we thank you for supporting our efforts to reduce sample bottle and cooler size.

ALS Safety PPI Metrics

| Metric | PPI Metric Description |

| Incident Frequency Rates | Total recordable injury frequency rate (regional business stream target) |

| Incident Frequency Rates | Lost Time Injury frequency rate (regional business stream target) |

| Incident Frequency Rates | No. of LTI incidents where >7 days are lost |

| Risk Management | Hazard Observation Reporting Frequency Rate as at 30 Sept |

| Risk Management | Hazard Observation Reporting Frequency Rate as at 31 March |

| Risk Management | Implementation of Critical Controls (%) |

| Leadership & Culture | Manager participation in site safety inspections (count) |

| Leadership & Culture | Completion of Leadership Site Inspection App as at 30 Sept |

| Leadership & Culture | Completion of Leadership Site Inspection App as at 31 March |

| Program Compliance | Close out of incident reports reported on compliance portal within 45 Days Ytd (%) |

| Program Compliance | Close out of Annual Compliance Sign-off Corrective Actions (%) |

| Training | New employees completed induction training (ALStar) |

| Training | Managers completion of compliance training in ALStar (Lost Time Injury Management) |

For further information please contact your local ALS Management team. We look forward to continuing the safety improvement journey with you and updating you next year.

Terminology

LTIFR – Lost Time Injury Frequency Rate. Lost-time injuries per million hours worked.

TRIFR – Total Recordable Injury Frequency Rate. The rate of recordable injuries per million hours worked.

LTI – Lost Time Injury.