EnviroMail 13 Canada

Laboratory Tests to Predict Acid Rock Drainage Impacts

Acid Rock Drainage (ARD) forms when sulfide-bearing materials are exposed to oxidizing conditions. Potential sulfide-bearing materials include waste rock overburden, processed ore (tailings) as well as exposed rock from either an open pit or underground mine. Sulfide minerals such as pyrite, pyrrhotite, and chalcopyrite in mine waste material can react with water and oxygen to produce sulfuric acid, which may in turn leach metals from the same material and introduce them into the environment at potentially high concentrations.

ARD can cause significant long-term environmental issues at mine sites if appropriate prevention and/or management strategies are not adopted. However, not all mining operations that have sulfide-bearing material result in ARD. In some scenarios, the sulfide minerals may be nonreactive or there may be sufficient buffering capacity available in the material to neutralize any acid released from sulfide oxidation. Samples with abundant neutralizing minerals such as calcite or dolomite may act to increase the natural pH in waters, thus preventing or mitigating acid drainage and metal run-off.

Since ARD risks are generally unknown and highly site-specific, it is necessary to gain a thorough understanding of the chemistry and leaching potential of site materials in order to effectively predict and manage ARD, and to minimize the risk of long-term liability.

ALS provides comprehensive analytical services to the mining industry to help identify and treat sources of acid rock drainage and the corresponding leaching of heavy metals into the environment. Our Vancouver BC laboratories (as well as ALS laboratories in Australia and South America) can conduct the following analyses in support of mining projects:

- Acid-Base Accounting (ABA)

- Humidity Cell Testing

- Column Leach Studies

- Shake Flask Extraction

Acid Base Accounting

Acid Base Accounting (ABA) procedures are used as a screening process to categorize materials into potentially acid generating and non-acid generating, in addition to determining the forms of sulfur and carbon that are present. For material where the potential for acid generation is uncertain, humidity cell testing is performed to help define acid generation potential and characteristics.

Humidity Cell Testing

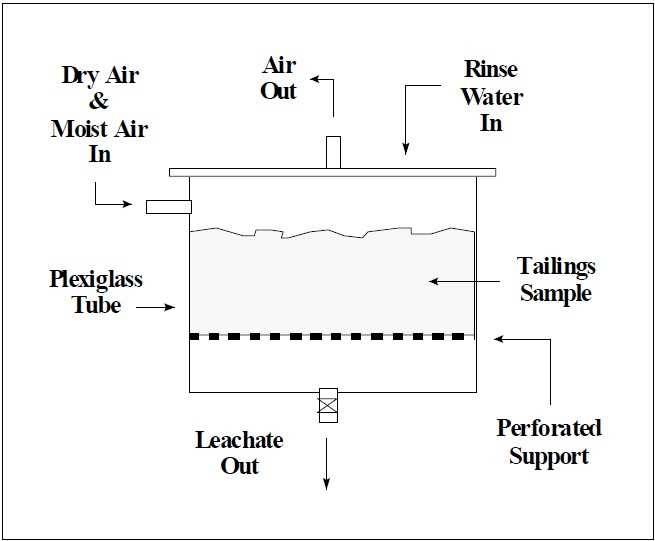

Humidity Cell Testing, also referred to as kinetic cell testing, is designed to mimic the weathering of samples (typically tailings or crushed rock) in a controlled fashion at the bench scale. The test determines the rate of acid generation and the variation over time in leachate water quality. One kilogram of dry, crushed (< 6.5 mm) rock samples is placed into a specially designed humidity cell apparatus, and is then subjected to weekly cycles that alternate between the circulation of dry air and moist air over the samples to simulate precipitation cycles.

Weekly humidity cell leachates are analyzed for a number of diagnostic chemical parameters, typically including acidity, alkalinity, anions (chloride, fluoride, sulfate, nitrate, nitrite), dissolved metals, pH, and conductivity, with additional tests added as required based on the material or project requirements.

Humidity cell design can be customized to meet a variety of client or site- specific needs. All ALS humidity cell sampling and laboratory analyses follow or are adapted from recognized reference methods such as ASTM D5744-18. Most humidity cell trials run for a minimum of 40 weeks, but many continue for several years or until leachate concentrations plateau or decrease.

Column Leach Studies

Column Leach Studies (also known as Trickle Leach Columns) are customized ARD simulations which are typically designed based on site-specific investigative criteria. Column leach studies can be either subaerial, simulating water exposure with exposure to air, or sub-aqueous, simulating water exposure without exposure to air. Test variables such as column dimensions can be established based on client needs.Shake Flask Extraction

The Shake Flask Extraction is a static solubility test procedure conducted on materials that are typically already oxidized as a result of historic enrichment processes, previous mining activity, or a delay in the use of preventive measures. The solubility of minerals can range based on composition and is also influenced by the leaching solution (normally deionized water), the contact time (normally 24 hours), and other environmental conditions. ALS offers several options for shake flask extraction methods, but the most common technique follows guidance from the MEND Prediction Manual for Drainage Chemistry from Sulphidic Geologic Materials.

Sample Submission Requirements

ARD-related tests can be performed on a variety of rock sample types, including waste rock, mine tailings, drill chips, grab samples, diamond cores, etc. Humidity cell tests require submission of approximately 2 kg of rock sample (samples with particle size > 6.5 mm are subjected to crushing to < 6 mm). A minimum of 500 grams of sample is requested for ABA tests.

Application of static and/or kinetic leach test procedures tailored to the circumstances of your site materials and conditions can help you to understand, predict, and mitigate the risks of acid rock drainage and metal leaching at your mine site.

Please contact ALS for more information.

References

MEND Report 1.20.1 (2009) Prediction Manual for Drainage Chemistry from Sulphidic Geologic Materials, Mine Environment Neutral Drainage program (Canada).

ASTM Method D5744-18 (2018), Standard Method for Accelerated Weathering of Solid Materials Using a Humidity Cell, ASTM International.