EnviroMail 03 USA

Fenceline Monitoring

In August 2017, ExxonMobil submitted a request to the US EPA regarding alternative testing procedures to Methods 325A and 325B (40 CFR 63, Appendix A). In response to this request, on September 11, 2017 the US EPA approved a number of planned revisions to the method, which can be utilized prior to the method’s projected formal revision date of 2018.

While the EPA letter specifically addressed ExxonMobil sites, the revisions may be applied to all fenceline monitoring programs in the US, as the EPA noted that “these alternative procedures are applicable to all of the facilities subject to 40 CFR 63, Subpart CC,” and that “our approval of this alternative is broadly applicable to fenceline monitoring under this subpart.”

The proposed alternative testing and method clarification address three major points:

1. How met data affects the sample calculations

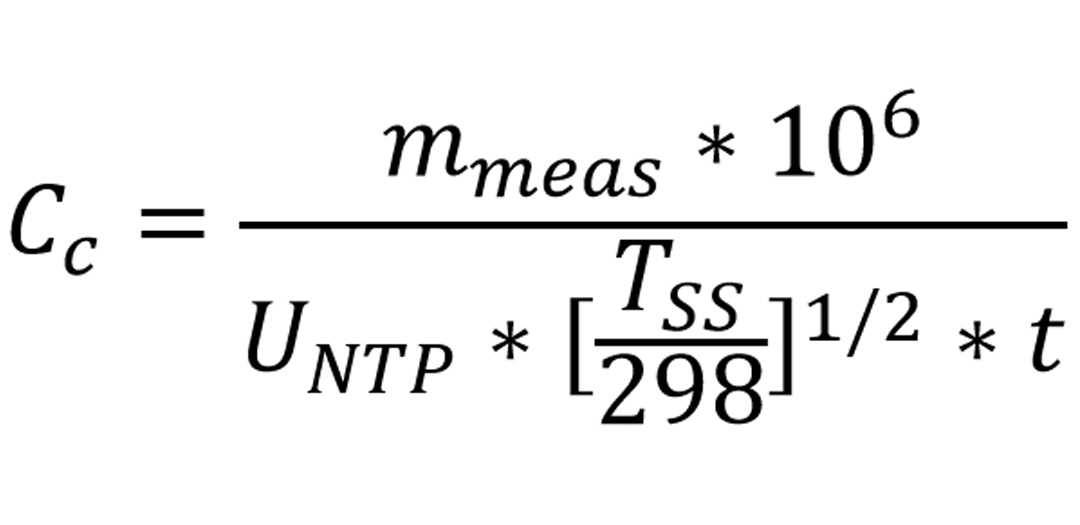

Equations 12.5 and 12.6 in EPA 325B, designed to correct the benzene results for local meteorological conditions, will now be simplified into the single equation for calculating analyte concentration:

Under the original rule, it was unclear how refineries should manage instances in which extenuating circumstances (ex., extreme weather or power failure) prevented or limited collection or deployment of samples within the method-specified 13-to-15 day range.

In the approval letter, US EPA provided guidance that the refinery simply document the conditions on the next routine reporting cycle and resume normally scheduled sampling as soon as feasible.

3. Approval to reduce the number of field blanks and duplicates

Under the original rule, it was specified that refineries must take one field blank for every ten field samples, with a minimum of two per deployment, and one duplicate must be taken for every ten field samples.

The rule now provides a reduction for field blanks and duplicates:

- For 19 or fewer monitoring locations, refineries must deploy one duplicate and one field blank.

- For 20 or more monitoring locations, refineries must deploy two duplicates and one field blank.

How does this affect previous pilot study data?

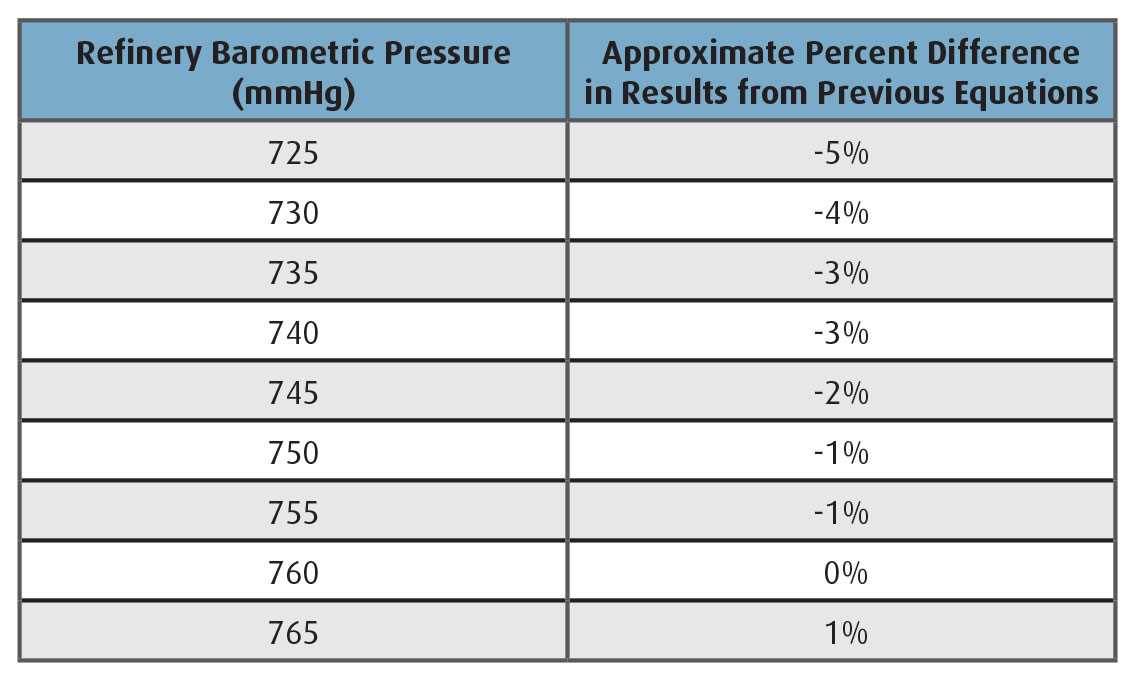

If your refinery is located where the barometric pressure is lower than 760mmHg, your results calculated after September, 2017 (using the alternative procedure) will show an approximate increase in the benzene concentration by 1-3%.The effect of the new calculation on the reported benzene concentration is summarized in Table 1.

How does this affect previous pilot study data?

It was determined that there was a derivation error in the original EPA 325B Equation 12.5. The revised equation, though similar, moves the temperature variable from the denominator to the numerator and raises the equation to the one-half power, rather than to three-halves.

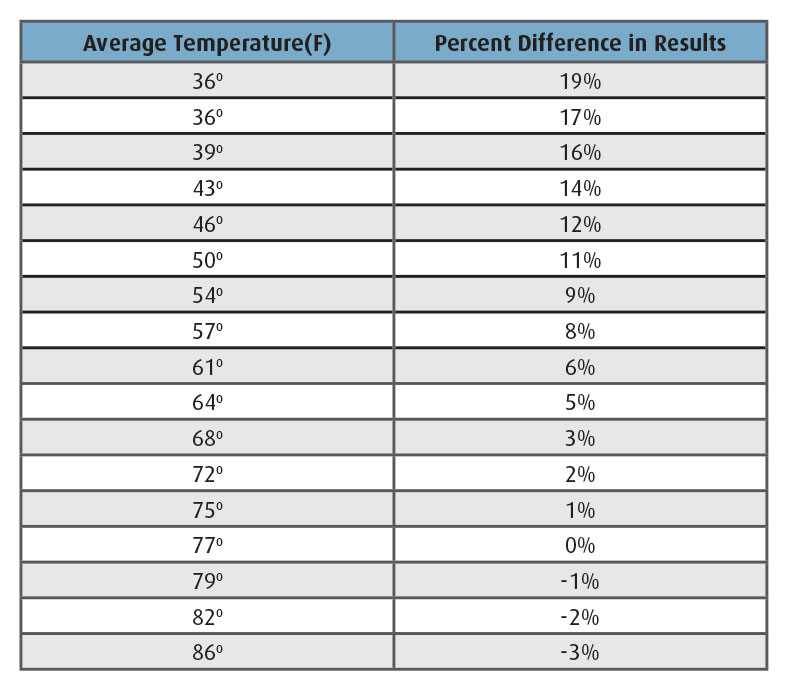

This change has the greatest impact on results calculated for geographical areas that reported an average temperature below 60°F.

Due to the extremely low volatility of benzene at low temperatures, however, the revision is not expected to have a significant effect on the overall ∆C concentration under most meteorological conditions.

The effect of the new calculation on the reported benzene concentration is summarized in Table 2.

Table 2: Effect of Temperature on Benzene Results *A positive percent difference indicates an increase in reported results, and negative percent difference indicates a decrease.

How can the laboratory assist me during extenuating circumstances?

In the case of Hurricane Harvey, for instance, many refineries chose to delay their deployments until their sampling staff could safely reach their remote monitoring locations. In this case the laboratory can assist with logistics: delayed or expedited shipments, pre-populated chain of custody revisions to reflect deployments outside of the typical 14-day period, or expedited sample analysis to align with timelines that could not be met due to the extenuating circumstances.

How will the reduction in field blanks and duplicates affect the rule implementation in 2018?

Can this change be immediately implemented for our pilot study?

The reduction in field blanks and duplicates reduces costs for refineries and streamlines the field quality controls while maintaining rigorous laboratory quality control protocols.

Site sampling requirements, sorbent tube deployment and collection, and laboratory protocols are not impacted by this revision, and there is no impact on the NELAP certification held by ALS for EPA 325B.

This revision can be implemented immediately; coordination with your laboratory Project Manager will ensure that the correct number of field blanks and duplicates are supplied with your sample tube shipment, and that all pre-populated chain of custody documents and labels are correctly generated for future deployments.

ALS will continue to inform you on any crucial changes prior to rule implementation in 2018 and provide ongoing technical expertise and support.

CLICK HERE to contact the refinery fenceline monitoring experts at the ALS laboratory located in Simi Valley, CA.