Mine-site laboratories

ALS operates across approximately fifteen on-site coal laboratories, ranging from 2-person operations to 20-person operations. These laboratories receive senior management oversight at regional laboratories and from mine-site focused supervisors. All employees on site have received appropriate training through the ALS Coal competency based training program, LabSkills, and process samples using the standard ALS Coal “Current Best Method” work instructions. All mine-site laboratories participate in the ALS Coal in-house round robin analysis program. All laboratories now also capture data via a Laboratory Information Management System (LIMS) which, if requested by the client, can directly upload data into the client’s data management system.

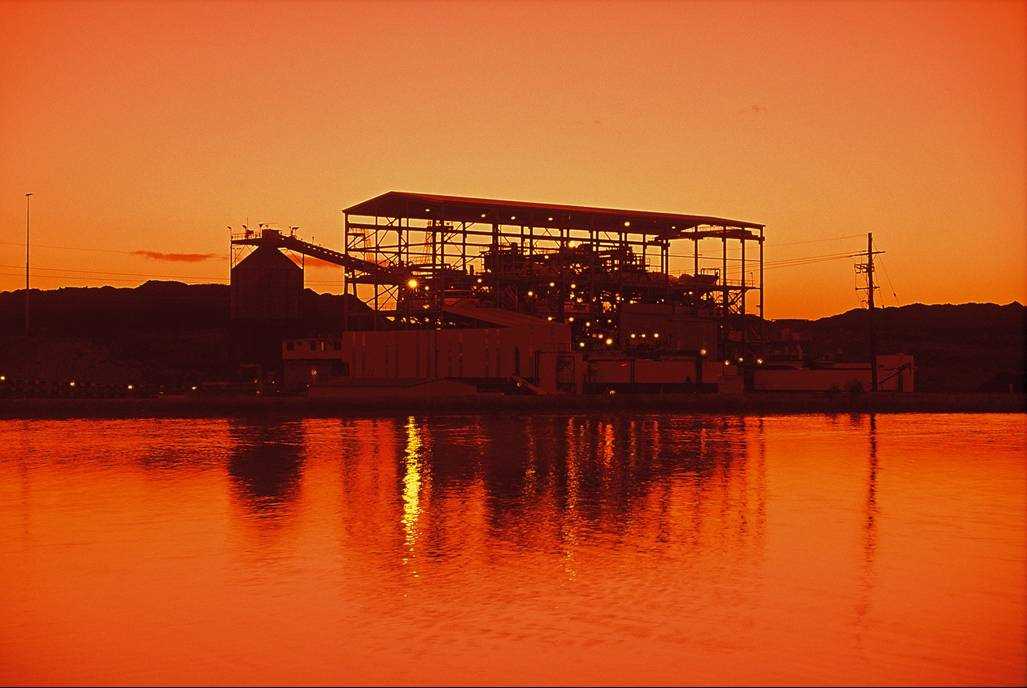

Modular laboratory solutions

Our modular laboratories allow coal mining companies to have a mine-site laboratory tailored to their mine’s requirements. These mine-site solutions comprise both a sample preparation and an analytical laboratory, with the scope of services defined by the mine-site prior to fabrication. ALS builds these modular facilities at the Richlands facility. Once fabricated, the electrical systems are approved by the site EEM prior to delivery, thus minimizing start-up delays.

New technologies

Innovation has allowed ALS to deliver safer, faster, and more controlled results on the mine-site. Recent innovations include:

- Crush–Rotary Sample Divider Systems are typically tailored to a particular mine-site’s requirements. Knowing the primary sample mass, the nominal particle top-size and the moisture content of the coal, a crush/divide system is designed and fabricated such that it will automatically to produce a -4mm product of the required mass (i.e. ready for milling). These units are fully enclosed with in-built dust collection systems and rejects collection systems.

- The Cyclone Milling System is a retrofitted cyclone sample collection system attached to commercially available striker mills. This process takes -4 mm coal to -212 µm while minimising fugitive coal dust and improving productivity through the mill.

- The dust suppression systems allow laboratories to be fully air conditioned which produces a better work environment and more focused employees.

Mine-site management systems

ALS sees significant value in monthly formal meetings with clients to review the performance of the mine-site laboratory. ALS also typically provides monthly “Client Heath Reports”. These documents provide information to the customer on 1) any OHS issues that have arisen during the month and how these items were addressed, 2) shift coverage, 3) turnaround times, 4) Quality System performance including any Corrective Action Requests (CARs) that may have been generated and the laboratory’s performance in round robin exercises.

Search

Search

English

English

Login

Login